The Japanese in Britain: Sharp Corporation

First published in Blueprint, October 1984

First published in Blueprint, October 1984What makes a multinational from Osaka set up in Manchester?

Of course, you can issue denials. Liberal impulses, an unfocused kind of internationalism – these suggest otherwise. But there’s no getting away from it: the presence of Japanese multinationals in Britain is just a little incongruous. An English friend of mine who works for McKinsey in New York and Tokyo maintains that Europe has more in common with Japanese mores than it does with America. The Japanese are, too, admired by productivity-conscious British managers, courted by jobless British borough councils, and wooed by no-strike-deal-seeking British unions (Terry Duffy’s AUEW, Clive Jenkins’ ASTMS). Yet somehow their operations here, though fascinating, appear other-worldly.

The incongruity is if anything heightened by the strenuous efforts the Japanese make to embed themselves in British culture. In the case of Sharp, a ¥1 trillion (£3 billion) electronics concern based in Osaka, the urge to submerge the Pacific in the North Sea verges on the bizarre. Sharp, which boasts 50,000 employees worldwide and 34 manufacturing plants outside Japan, has its emphatically red post-MacArthur logo emblazoned on the shirts of every one of the vests worn by the soccer stars of Manchester United, FC. What Matt Busby would say is anybody’s guess; but Sharp’s sponsorship deal with United – it includes a lavish suite of restaurant tables and grandstand seats at Old Trafford – is the largest ever agreed by a British club.

How they are penetrating

Ten years ago, Sharp’s UK turnover was less than £8 million. Today the figure is about £150 million and leaping up: the company’s British offshoot is the fastest-growing of all its overseas subsidiaries. The bulk of business is in consumer goods, but long-term growth is likely to be greatest in office gear. For the moment, however, the major development for Sharp Electronics (UK) will be the construction of an 18,000 m², £15 million video-recorder factory on 27 acres of turf at Wrexham, North Wales. Designed by Building Design Partnership, the plant promises to channel 60,000 machines in its first year and, eventually, add 600 jobs, most of them blue-uniformed and name-tagged, to the 250 which Sharp maintains at its giant sales, service and warehousing headquarters in Manchester.

Just, then, as Hoover, General Motors and other American firms brought divisionalised corporate structures to the recessionary Britain of the 1930s, so Sharp, Nissan and the Japanese bring product reliability, quality circles and all the rest to the recessionary Britain of the 1980s. Whether the Brits will really benefit from Japanese managerial practice is debatable; it took them decades to go divisional à la USA, and even then the move didn’t seem to help much. Also, the Financial Times reported earlier this year that, though there are efforts to resuscitate, getting on for half of the quality circles in British industry have collapsed.

Yet these thoughts are thankfully distant as you hurtle up the motorway from Manchester in the Sharp courtesy bus.

On the bus they play you Circles of fame, a surprisingly diverting video on the history of the Olympic Games, complete with some nicely jerky prewar footage (made by Sharp, the vid comes free with every VCR). Then they play you the company video, which is where the fun starts.

The thing that strikes first about Sharp’s different corporate interiors is that they are – I kid you not – electroluminescent greenish yellow. The air itself appears yellow. Partly the interiors look like this because they are interiors of ‘clean room’ laboratories for making Very Large Scale Integration chip masks (the men are in masks too). But even the factories are in the same colour. And the factories… Wow! It’s not just that Sharp, the people who first visited pocket calculators on the world, now pop one out every four seconds; nor that the Sharp line which make microelectronic-controlled plain paper copiers (another company world first, 1977) is nearly a mile long. No, the most most disturbing thing is that the lines are six deep, covered with covetable TVs, that the TVs and the lines move in opposite directions and that there’s nobody there.

If Circles of fame is anything to go by, some of this may be just a video editor’s artifice. But that hardly matters. For as Sharp’s most Mancunian marketing men confirm, Osaka is faced with our old friend, the problem of overproduction (their words, not mine) – especially in video recorders. Despite or perhaps because of its astounding lines, its Sharp-made robots and its fridges built by Flexible Manufacturing Svstems, Sharp’s ultra‑low prices can all too easily not be low enough to sustain the demand necessary to meet its enormous production volumes. The multiple features which are themselves the main feature of Sharp products, can, the Mancunians admit, get ‘skinned’ down to meet those £9.95 sales tags; but ‘everybody’s only got two eyes and ears – you can’t sell a family of six all of eight hi-fis’.

In the EEC market for VCRs the situation is even tougher. There, in a prescient move, Philips has made sure that Japanese manufacturers are almost bound to overproduce. Not so long ago, the Dutch multinational pressured the Brussels Commission to hit back against import of Sanyo Betamax machines. As a consequence, Japan’s MITI agreed to limit volumes for all the video recorders it exported to Europe (remember, in 1981 Britain’s trade deficit in VCRs outweighed that in cars, a hefty one by any standards). Result: prices rose and demand fell so rapidly that Japan had to cut EEC exports from 2m units to little more than 1m – fewer even than the total to which Brussels had limited them.

Here is one of the reasons why Sharp has decided to build VCRs on British soil. Since Philips dropped its V2000 format and opted, at long last, to make VHS machines, a complete Brussels ban on Japanese imports has become more likely. Philips employs a lot of people in the EEC, and Eurocrats are more than a little sensitive to its needs. The only guaranteed way round this is to set up factories inside the citadel of the Ten itself.

Grow the chips

Life was a lot simpler in 1915, when Sharp gained itself a name with a self‑propelling pencil, the Ever‑Sharp. Overproduction? In 15 years’ time, Sharp chief scientist Dr Suzaki maintains, chips will be grown in cultures. Currently, Sharp is doing well with its photovoltaic cells, made of amorphous silicon, rolled off, carpet‑like in extraordinary rows to be used in unmnanned lighthouses and Japan’s own space satellites; but by the year 2000, Suzaki contends, the only money to be made will be outside manufacturing – in software, expert systems and artificial intelligence. In the meantime, Sharp’s strategy is to stay ahead of the game in consumer goods, both by stressing non-price factors and by racing down the price curve on big product innovations, and to move into office automation. In each case, however, obstacles exist which could make its ride in Britain a rather bumpy one.

Spearheading Sharp’s non‑price initiatives is its QT (“Cutie”) radio. Equally stylish in colour (light purples and the like) and form (thick radiuses, nicely finished plastics) are its tiny pre-set wavelength personal radios, for locking into its answer to Sony’s cassette playing Walkman. But though QTs are now selling in Virgin stores, it takes five months to bring a new product like them from Japan to Britain – a long period for the fashion-conscious lines Sharp now wants to move into, and one that brings risks. On the other hand the personal radios have flopped. Their small size made them easy prey for British shoplifters and therefore unpopular with British dealers, and their very discretion in design terms gave them low ‘perceived value’ with British consumers.

All this points to a broader problem. Along with JVC, Sanyo, and, arguably, Panasonic, Sharp provides the cheap audio and audio-related products that are the staple of London’s Tottenham Court Road. Sony is an altogether more prestigious operation, celebrated as it is in the V&A’s Boilerhouse exhibition space. Indeed as far as aesthetics go, Sharp has a lot of catching up to do if it is to start setting standards. Thus unlike the success of Continental car manufacturers (Volkswagen, Fiat) in Britain, that of Sharp and other Japanese hi‑fi manufacturers attests not to the innate good taste of the Great British Public when offered something decent as against British‑made products, but to the more down‑market malleability of the Great British Public when offered no alternative (for there are even fewer British‑made hi‑fis than there are British‑made cars). In short, Sharp not only has its work cut out making sure that its products lose their ‘styled in Japan’ image; it also has a lot of mass visual education to pursue if its move out of high output/low margins is to amount to anything. Weaned on Sharp silver ghetto‑blasters, cosmetic signal‑to‑noise graph decals and garish flashes on Sharp cassette windows. the British masses who don’t buy Sony will not adopt modest looks and intelligible fascias overnight. Sharp’s current mass experiments in colour – its radio recorders are a rather too sun-burnt red – show how slow the going is likely to be.

As for going down the price curve and automation, these too have their difficulties. Compact Disc machines will have to drop from £299 to £199 for Britons to buy them in quantity, and DIY video‑making will have to take a tumble from £999 to £599.

In office gear Sharp’s expectations are high – it anticipates that consumer products will overtake office ones considerably in future years, and to this end launched an all red-keyboard-cum-TV number‑cruncher two years ago. Its 16-bit, IBM‑compatible PC 5000 personal computer impressively hooks into British Telecom’s mains-connected Telecom Gold communications system, fits into a suitcase and can do dot‑matrix print‑outs with letters smaller than the type you’re reading now. But Sharp has entered the UK business technology market late. Its electronic typewriters, for instance, look more than a little archaic – even against Olympia, and certainly against Olivetti.

Take‑off from Tarbuck

Sharp deserves to succeed in Britain. We can do without ‘Sharp’s Business Creed’ at the front of its glossy literature (‘Harmony is power… Trust each other for a united effort’, etc). No Sharp pocket translators, complete with liquid crystal displays asking ‘DO YOU SPEAK ENGLISH?’ will ever improve the performance of British tourists abroad. And you’ll not find a Sharp microwave oven in my kitchen so long as Jimmy Tarbuck gesticulates in front of them from the side of London buses, or so long as most of them look gaudy kebab-shop rather than sleek Zanussi (and though they’re just as safe as food mixers, they’ll never do a Yorkshire pud). But the fact remains that microwave ovens significantly lighten women’s load in the home; that shop sales will hit the million mark this year, and that the company shows sensitivity to British culinary conservatism in offering two-day cooking schools for buyers of its products and their friends. For free, too.

Fmr President of Kenya on Trump cutting off foreign aid:

“Why are you crying? It’s not your government, he has no reason to give you anything. This is a wakeup call to say what are we going to do to help ourselves?”

America first is good for the world.

Our entire Green Socialist establishment should be banged up under the ‘Online Safety’ laws, for spreading demonstrable lies (the ‘climate crisis’), causing non-trivial harm to the industrial working class, ordinary drivers, farmers, taxpayers etc, etc.

#Chagos? #Mauritius PM Navin Ramgoolam "is reported to want Starmer to pay £800m a year, plus ‘billions of pounds in #reparations’." (14 January) https://www.spiked-online.com/2025/01/14/the-chagos-islands-deal-is-an-embarrassment/

Now the Torygraph wakes up https://telegraph.co.uk/gift/1ff8abbb462cd609

Read @spikedonline - first with the news!

Articles grouped by Tag

Bookmarks

Innovators I like

Robert Furchgott – discovered that nitric oxide transmits signals within the human body

Barry Marshall – showed that the bacterium Helicobacter pylori is the cause of most peptic ulcers, reversing decades of medical doctrine holding that ulcers were caused by stress, spicy foods, and too much acid

N Joseph Woodland – co-inventor of the barcode

Jocelyn Bell Burnell – she discovered the first radio pulsars

John Tyndall – the man who worked out why the sky was blue

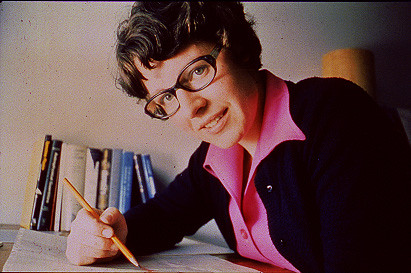

Rosalind Franklin co-discovered the structure of DNA, with Crick and Watson

Rosalyn Sussman Yallow – development of radioimmunoassay (RIA), a method of quantifying minute amounts of biological substances in the body

Jonas Salk – discovery and development of the first successful polio vaccine

John Waterlow – discovered that lack of body potassium causes altitude sickness. First experiment: on himself

Werner Forssmann – the first man to insert a catheter into a human heart: his own

Bruce Bayer – scientist with Kodak whose invention of a colour filter array enabled digital imaging sensors to capture colour

Yuri Gagarin – first man in space. My piece of fandom: http://www.spiked-online.com/newsite/article/10421

Sir Godfrey Hounsfield – inventor, with Robert Ledley, of the CAT scanner

Martin Cooper – inventor of the mobile phone

George Devol – 'father of robotics’ who helped to revolutionise carmaking

Thomas Tuohy – Windscale manager who doused the flames of the 1957 fire

Eugene Polley – TV remote controls

0 comments