Our hero: Gensets provide critical power where it’s needed

First published by IDG Connect, August 2015

First published by IDG Connect, August 2015After April, when Nepal suffered its worst earthquake in 80 years, the technology made it to the front page of the New York Times. In the capital, Katmandu, nighttime blackouts had previously been routine. As a result, many of the city’s hotels, commercial buildings and wealthy homes had had their own diesel – and gas-powered electricity generators. But after the earthquake, power in Nepal, which is largely hydroelectric, was intermittent at best. At the same time, however, supplies of diesel and gas for generators could not get in to the capital from India.

So generating sets, the IT-laden resuscitation apparatus for any country faced with power cuts, could only help the stricken state to the extent that local stores of fuel were available.

The case of Nepal alone says a lot about an unsung hero: gensets, the industry term for the whole apparatus of engine, generator (usually an alternator), starting and control systems, sound attenuation, circuit breakers (rather important) and fuel tank. To my inexpert eye, gensets are no classic of engineering design. Yet their advocates are as passionate about them as Formula 1 buffs are about a Ferrari; and when they kick in, they frequently save lives – not only after disasters, but also on those occasions when hospital operating tables are denied electricity from conventional sources.

A genset to power a couple of offices or shops will cost perhaps £1,500. If you want to go through installing one to power a large hospital, you’re looking at a total cost of more like £250,000. Other applications of gensets also show their worth. Apart from being essential to datacentres, they are active around mines in remote locations, on off-shore oil rigs, at rock festivals and in construction. In rural Africa and elsewhere, diesel generators are often the only easily available local source of energy or means of purifying water; alternatively, in hybrid energy sources, they serve as a fallback to wind and solar power.

Then there’s the 224-metre Leadenhall Building, in the City of London (better known as the Cheese-grater). It houses heavyweight dealing-room floors for heavyweight finance. There, in August 2013, a firm of genset specialists named Broadcrown craned in, through a tight slot in the roof, four 18-tonne, 2MW, $1.4m containerised standby diesel generators on to the 47th and 48th floors. Just to help keep London’s circuits of electronic money moving in the eventuality that normal sources of electricity fail. (There is a sublime video of the installation by crane here at 9:22.)

We live in a world where nearly anybody could plausibly argue that his or her job is ‘mission-critical’. Yet diesel and gas generators can have that title with real justice. Their operational quirks, and those of the web with which the modern-day grid is controlled, make them need clever electronic protection. They have web-based remote monitoring for engine control, and use IT to log data from the grid, sense fuel levels, cool systems and perform remote maintenance. By 2017/18, indeed, the EU hopes that IT will underpin mandatory codes among transmission system operators so as to assure grid stability among and between member states. Here, once again, gensets are called in to make up for the weaknesses of renewable energy. This time, though, their IT has to help them play a role balancing a grid that’s been made unstable by the advent of wind and solar power.

I declare an interest. In London not so long ago I gave a speech for Britain’s Association of Manufacturers and suppliers of Power Systems and ancillary equipment (AMPS). But that doesn’t prevent me from observing that user interfaces on some of the older gensets I’ve seen are, frankly, pretty prehistoric. Still, things are changing. Telemetry has improved enough for smartphones and tablets in one country to be able adroitly to control the newer kind of genset in another.

There’s a need for better data visualisation. This, perhaps, is a consequence of the industry that was, in the past, overly concerned with innovating around its relatively negligible impact on emissions of CO2. That may have made it rather underplay innovation around the user-friendly side of IT.

Where there remains an environmental case to answer is the way gensets generate metallic hazardous air particulates (HAP). There, the EU may follow in America’s wake, and impose some stringent regulation.

Britain is no slouch in making gensets. Their soundproofing is getting better; their weights and footprints on the ground, 25% smaller. In 2013 Britain imported less than $100m of gensets, but managed to export kit worth no less than $1.4bn. AMPS insists that Britain is one of the world market leaders in generators, supplying perhaps 24% of world demand.

More generally, some big names dominate the genset industry: Caterpillar, Cummins, Deutz, Honda, Perkins, Scania, Volvo. There are alternator specialists such as Emerson, Marathon, MarelliMotori SpA and Mecc Alte SpA. And, in circuit breakers, there are ABB’s new, cool-running sort, the outcome of 1300 prototypes. They track electrical networks, and so lay the basis for root cause analysis. They also do predictive maintenance.

In an era where power cuts are more frequent and prolonged than in the past, the industry that makes generators and ancillary technologies has a lot in its favour. Now is the time for it to lighten up about global warming, and instead take even greater care of business around IT.

Fmr President of Kenya on Trump cutting off foreign aid:

“Why are you crying? It’s not your government, he has no reason to give you anything. This is a wakeup call to say what are we going to do to help ourselves?”

America first is good for the world.

Our entire Green Socialist establishment should be banged up under the ‘Online Safety’ laws, for spreading demonstrable lies (the ‘climate crisis’), causing non-trivial harm to the industrial working class, ordinary drivers, farmers, taxpayers etc, etc.

#Chagos? #Mauritius PM Navin Ramgoolam "is reported to want Starmer to pay £800m a year, plus ‘billions of pounds in #reparations’." (14 January) https://www.spiked-online.com/2025/01/14/the-chagos-islands-deal-is-an-embarrassment/

Now the Torygraph wakes up https://telegraph.co.uk/gift/1ff8abbb462cd609

Read @spikedonline - first with the news!

Articles grouped by Tag

Bookmarks

Innovators I like

Robert Furchgott – discovered that nitric oxide transmits signals within the human body

Barry Marshall – showed that the bacterium Helicobacter pylori is the cause of most peptic ulcers, reversing decades of medical doctrine holding that ulcers were caused by stress, spicy foods, and too much acid

N Joseph Woodland – co-inventor of the barcode

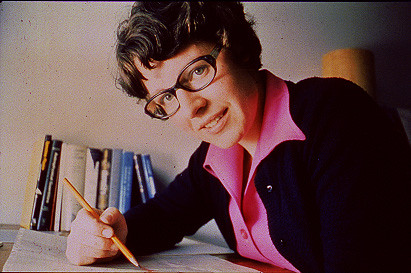

Jocelyn Bell Burnell – she discovered the first radio pulsars

John Tyndall – the man who worked out why the sky was blue

Rosalind Franklin co-discovered the structure of DNA, with Crick and Watson

Rosalyn Sussman Yallow – development of radioimmunoassay (RIA), a method of quantifying minute amounts of biological substances in the body

Jonas Salk – discovery and development of the first successful polio vaccine

John Waterlow – discovered that lack of body potassium causes altitude sickness. First experiment: on himself

Werner Forssmann – the first man to insert a catheter into a human heart: his own

Bruce Bayer – scientist with Kodak whose invention of a colour filter array enabled digital imaging sensors to capture colour

Yuri Gagarin – first man in space. My piece of fandom: http://www.spiked-online.com/newsite/article/10421

Sir Godfrey Hounsfield – inventor, with Robert Ledley, of the CAT scanner

Martin Cooper – inventor of the mobile phone

George Devol – 'father of robotics’ who helped to revolutionise carmaking

Thomas Tuohy – Windscale manager who doused the flames of the 1957 fire

Eugene Polley – TV remote controls

0 comments