Origins and future of Industry 4.0

First published by Blueprint in April 2017

First published by Blueprint in April 2017At the University of Missouri’s Center for Eldercare and Rehabilitation Technology, professors of engineering and nursing hook up sensors to perform clever feats in medicine. Under a bed mattress occupied by a senior citizen in his or her home, four hydraulic transducers, each a flexible tube of water, together capture heart rate, respiration rate, overall cardiac activity and sleeping patterns. The transducers pick up the mechanical effect of blood circulation. Their purpose, once the data coming from them are analysed: to warn of impending heart failure.

On the other hand, Missouri’s Doppler radar sensors, when mounted in the home, monitor how fast a senior citizen is walking (‘gait speeds’). That should help doctors determine the risk of the person suffering a fall in future.

These medical applications of the Internet of Things (IoT) matter more than consumer ones. Still, the IoT has come to Western kitchens. An Amazon Echo or a Google Home can control several household gadgets – heating, security cameras – in a systematic way.

The big prize with the IoT, however, lies not in the home, nor even in medicine, but in industry, and especially in manufacturing. Described as the Industrial Internet of Things, or by the still more exotic phrase Industry 4.0 (I4.0), it is the application of the IoT, or ‘cyber-physical systems’, to factories, process industries and supply networks. Here as elsewhere, the IoT is about sensors, machine-to-machine connections, and means of analysing and acting upon the data unleashed.

At the Hanover Fair (2011) and the World Economic Forum (2016, under the broader concept of Fourth Industrial Revolution), I4.0 was born not as bottom-up technological progress, but as a top-down economic and political rehabilitation of industry in the wake of the financial disaster of 2008. It was a concept of global elites, but also a specially German one. Germany’s strengths in manufacturing still go alongside weakness compared to America in IT, and exorbitance compared to China in wages. In German hands, therefore, I4.0 quickly became popular, as Berlin upheld an industrial policy that favoured a renewed digitisation of factories, not least given trade competition from China, China’s purchases of German high-tech companies, and China’s reputed barriers to German businesses on the Chinese market.

The ambitions of I4.0 were also Teutonic. Unlike the plain vanilla IoT, an I4.0 production system is meant to include a detailed virtual engineering model covering perhaps hundreds of machines at home and abroad. It’s meant to be modular over hardware and software; integrate and analyse engineering data in real time; allow human beings to communicate with it easily, and be designed so that machines are able to make decisions on a decentralised basis.

By the time we hear that the components, machines and a full-on I4.0 production system must be self-aware and self-organising, the gap between the technological realities of I4.0 and the political hype around it is all too clear. Nevertheless, I4.0 ought to bring, to the West, more than much-needed improvements in productivity. With more sensors and better data about production processes and supply networks, designers should be able to look forward to higher finished product quality and reliability – important, given the spread of product returns afflicting consumer goods manufacturers nowadays. In the medium term, I4.0 should lead to significant product and system redesigns: provided that all the data picked up by both factories and by products in the field can be visualised, analysed and acted upon, it should should make for serious innovation.

In the longer term, the IoT ought to be supplemented and advanced by research collaborations around an international Internet of Ideas, as have now emerged in archaeology and astronomy. But, so far, it isn’t right to speak of the ‘rise’ of the more advanced capabilities that comprise I4.0. There’s merely a gradual diffusion of knowledge and technology, slowed by a crisis of capital investment in the West, and by the feeling that I4.0 immediately opens up industry to cyber-attacks.

For the present the IoT too often means sweating assets (for example, in oil and gas), postponing investments in maintenance, having quarrels over physical and data assets, and using, in shops, ‘video analytics’ to track shopper and employee conduct. In fact, however, the future with the IoT lies elsewhere – in actuators.

A Malaysian firm’s Kissenger app may show the way here. It uses a mobile phone add-on to sense the movement of your lips, transmit them in data form, and turn them, with the help of miniature linear actuators, into what the firm calls ‘a realistic kissing sensation’ for your partner.

A primitive application, yes; but all hail the Internet of Flings!

Good luck to the #farmers on their march today!

I probably don't need to tell you to wrap up warm. But please remember that no part of the UK's green agenda is your friend. All of it is intended to deprive you of your livelihood, one way or another. That is its design.

Brilliant piece by @danielbenami. RECOMMENDED

Articles grouped by Tag

Bookmarks

Innovators I like

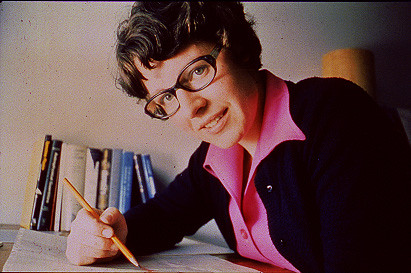

Robert Furchgott – discovered that nitric oxide transmits signals within the human body

Barry Marshall – showed that the bacterium Helicobacter pylori is the cause of most peptic ulcers, reversing decades of medical doctrine holding that ulcers were caused by stress, spicy foods, and too much acid

N Joseph Woodland – co-inventor of the barcode

Jocelyn Bell Burnell – she discovered the first radio pulsars

John Tyndall – the man who worked out why the sky was blue

Rosalind Franklin co-discovered the structure of DNA, with Crick and Watson

Rosalyn Sussman Yallow – development of radioimmunoassay (RIA), a method of quantifying minute amounts of biological substances in the body

Jonas Salk – discovery and development of the first successful polio vaccine

John Waterlow – discovered that lack of body potassium causes altitude sickness. First experiment: on himself

Werner Forssmann – the first man to insert a catheter into a human heart: his own

Bruce Bayer – scientist with Kodak whose invention of a colour filter array enabled digital imaging sensors to capture colour

Yuri Gagarin – first man in space. My piece of fandom: http://www.spiked-online.com/newsite/article/10421

Sir Godfrey Hounsfield – inventor, with Robert Ledley, of the CAT scanner

Martin Cooper – inventor of the mobile phone

George Devol – 'father of robotics’ who helped to revolutionise carmaking

Thomas Tuohy – Windscale manager who doused the flames of the 1957 fire

Eugene Polley – TV remote controls

0 comments