Planned obsolescence: winter of the tastemakers

First published in Management Today, January 1989

First published in Management Today, January 1989High-tech consumer durables have a reputation for falling apart. But planned obsolescence does not account for the problems of repair.

For three weeks this winter I have endured the most appalling agony. First, my middle‑market Philips car stereo quite reasonably decides to chew up a rather battered old rock tape. Then I bring the machine in for mending, but that takes an age. I have to fight through London’s jammed but lonely streets for a full 20 days without music as a friend.

Rapid repair of defective consumer products, it appears, has become a dying art. For at just the moment that my car has turned from roving jukebox to mobile morgue, I gain an insatiable desire to get my Hitachi tape player at home fixed; and that operation, too, is beset by interminable delays. With my three-year-old piece of Philips in‑car entertainment, I only have what quaintly translated instruction manuals call ‘tape spaghetti’, complicated by the need for a trivial missing part that never arrives. By contrast, my Japanese ghetto‑blaster – black, aggressive, up‑market, manufactured around 1981 – has a faulty gas-operated tape loading mechanism, a dead power switch and a gnawed‑at microphone. Repair, I am told, will take two or three months.

Many Japanese consumer electronics companies do have rather poky after‑sales counters at their massive UK HQs near Slough. But Slough is too much of a trek to make just to get a ghetto-blaster fixed; so I go, on Hitachi’s recommendation, to a dealer on London’s Tottenham Court Road. There two repairers are ill and on holiday. They will do an estimate and that alone will cost me, whatever I decide to do. Late on a wet Friday night, I meekly agree.

The following Monday the Zanussi dishwasher collapses. ‘Can we send an engineer on Friday?’, Zanussi asks my wife on the phone. Only when she insists on Wednesday is that agreed.

This is a contest we win, for Zanussi does indeed show up on the appointed day, and rehabilitates our machine within minutes by removing an errant part from the pump. Nevertheless, I am nervous. The Christmas before last, I had to play the ‘I am a journalist and I demand to speak to the marketing director’ card to AEG. That was over our washing machine. The company told me then that it had had to recruit extra service engineers to deal with Yuletide demand. It was hard to raise an answer from AEG on the phone and our youngest’s dirty clothes soon assumed mountainous proportions.

Though all our household’s basic life support systems once again appear near a Challenger‑style ‘major malfunction’, we decide to buy an AEG gas oven. But just then our 14inch Panasonic Quintrix television gets white lines running over it like the running track at the Seoul Olympics. This time we use Yellow Pages: a local man and his son come round and manage to right it, in our home, for £22, then take it away when it goes wrong, and finally bring it back perfect. For a further £10, they fix everything and, in a now highly unfamiliar symbol of personal service, attach the plug to the telly by doing the necessary high‑exertion wire-chasing behind our bookcase. Total bill: £33.

According to our TV repairers. today’s video cassette recorders, hi-fi sets and the like last longer than in the past. But when they do go en panne, the properly working part replacing the defective part now has too many integrated circuits on it to be inexpensive any more. Worse, the rate of new product development in manufacturing is now so rapid that spare parts, even for popular products, can fall out of stock within as little as 18 months. What’s really happening, the repairers argue, is that manufacturers are deliberately making their wares impervious to resuscitation. The reason: this way, they hope to encourage more replacement sales in the future.

These hassles surrounding professional surgery on consumer goods are of some moment. As consumer expenditure slows under Chancellor Lawson’s squeeze, more and more people will find themselves unable to swap kit that’s kaput for the working variety. There will be more attempts by the lay public to patch up appliances at home, and thus, we may conjecture, more living room electrocutions, soldering iron burns, fingers frazzled in fan belts. Men, it is true, may go on buying Motorola car phones, Sanyo twin-speed VCRs, Hitachi computer speed controlled shavers with rhodium foils, Philips picture-in-picture Grandstand. But even they will find breakdowns hard to reverse. As for women vacuuming, cooking and washing with products in the home – Britain’s enormous, unseen, unpaid economy of women doing housework – their lives may gradually grind to a halt.

At this point you might well ask, nimbly: ‘Doesn’t all this hassle with product repairs amount to just a new form of planned obsolescence?’ Can’t the techno-economic unmendability of objects, like the tendency for their aesthetics to go out of style – can’t these things be laid at the door of the modem‑day design consultant, conspiring with manufacturers to rip innocent consumers off?

Perhaps. But after 12 years in design, I’ve yet to find such a conspiracy. Designers are usually too pressed for time, too idealistic to have a confab with their clients about when the products of their labour at the drawing-board or CAD screen should fall to bits.

To open and download a PDF copy of this article, click on this Winter of the wastemakers link.

Consider a little history. The term ‘planned obsolescence’ was first popularised by the American muck‑raking journalist Vance Packard in his hilarious book The Waste Makers (1960). Packard stressed that planned obsolescence was essential for high consumption that, in turn, was essential if America’s heavily automated factories and offices were to keep up demand for their wares. In a US of booming productivity, the recession of 1957-58, the worst of three since the war, served to remind everyone of the pivotal role of consumer expenditure, as inventories soared, overcapacity mounted and unemployment became ‘worrisome’. Planned obsolescence, Packard argued, was a response to this.

The significance of Waste Makers is that today’s consumer products operate in a completely different environment. They last longer, are becoming cheaper and – in contrast to what Packard criticised in the products of 1960 – often contain some genuine feature innovations. More importantly, British consumers today are not recovering from a mini‑recession in the midst of a successful (‘hyper‑thyroid’) production economy. On the contrary, we are entering a renewed recession. The context for today’s irreparable products is, therefore, much bleaker than that surrounding the gleaming finned Cadillacs of General Motors’ chief stylist Harley Earl, a major enthusiast for what he called ‘dynamic obsolescence’.

In Packard’s account, evil wastemakers like Earl joined furniture designer George Nelson and the marketing guru Theodore Levitt in upholding the merits of a throwaway culture. But the old hack’s case was always less sensational than he made out. Earl had, with his boss Alfred Sloan, been pioneering planned obsolescence since the late 1920s – through GM’s policy of annual model changes. Moreover, in retrospect we can now see that Packard’s America was never as automated and thus plagued with overproduction as he made out. Last, even if some designers were at fault, Packard had to admit that giants like Raymond Loewy, Walter Dorwin Teague and Gordon Lippincott all said no to planned obsolescence.

Today, we may be certain, there is still little planned obsolescence. It is just that products go wrong, and that our expectations are high. Still, something needs to be done: for a start, we could do with more experiments in self‑diagnostic fault displays on products, and with clearer guides to owner repair.

Why does something need to be done? Because Packard wrote at a time when America was reaching her sunny peak. Because here in gloomy winter Britain, we have designers, but no repairers – so that when your car radio or dishwasher gives up the ghost, you really suffer.

Fmr President of Kenya on Trump cutting off foreign aid:

“Why are you crying? It’s not your government, he has no reason to give you anything. This is a wakeup call to say what are we going to do to help ourselves?”

America first is good for the world.

Our entire Green Socialist establishment should be banged up under the ‘Online Safety’ laws, for spreading demonstrable lies (the ‘climate crisis’), causing non-trivial harm to the industrial working class, ordinary drivers, farmers, taxpayers etc, etc.

#Chagos? #Mauritius PM Navin Ramgoolam "is reported to want Starmer to pay £800m a year, plus ‘billions of pounds in #reparations’." (14 January) https://www.spiked-online.com/2025/01/14/the-chagos-islands-deal-is-an-embarrassment/

Now the Torygraph wakes up https://telegraph.co.uk/gift/1ff8abbb462cd609

Read @spikedonline - first with the news!

Articles grouped by Tag

Bookmarks

Innovators I like

Robert Furchgott – discovered that nitric oxide transmits signals within the human body

Barry Marshall – showed that the bacterium Helicobacter pylori is the cause of most peptic ulcers, reversing decades of medical doctrine holding that ulcers were caused by stress, spicy foods, and too much acid

N Joseph Woodland – co-inventor of the barcode

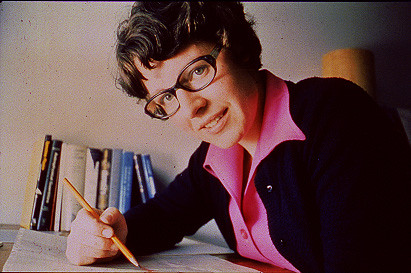

Jocelyn Bell Burnell – she discovered the first radio pulsars

John Tyndall – the man who worked out why the sky was blue

Rosalind Franklin co-discovered the structure of DNA, with Crick and Watson

Rosalyn Sussman Yallow – development of radioimmunoassay (RIA), a method of quantifying minute amounts of biological substances in the body

Jonas Salk – discovery and development of the first successful polio vaccine

John Waterlow – discovered that lack of body potassium causes altitude sickness. First experiment: on himself

Werner Forssmann – the first man to insert a catheter into a human heart: his own

Bruce Bayer – scientist with Kodak whose invention of a colour filter array enabled digital imaging sensors to capture colour

Yuri Gagarin – first man in space. My piece of fandom: http://www.spiked-online.com/newsite/article/10421

Sir Godfrey Hounsfield – inventor, with Robert Ledley, of the CAT scanner

Martin Cooper – inventor of the mobile phone

George Devol – 'father of robotics’ who helped to revolutionise carmaking

Thomas Tuohy – Windscale manager who doused the flames of the 1957 fire

Eugene Polley – TV remote controls

0 comments